Find your Country and language

Lubricants Beyond Today's Standards TM

Petro-Canada™ Lubricants' distribution network extends to over 80 countries worldwide

This website uses cookies. By continuing to browse this website you are agreeing to our use of cookies. Find out more by reading our privacy policy.

Excluding the regions of Crimea, Donetsk and Luhansk

Petro-Canada™ Lubricants' distribution network extends to over 80 countries worldwide

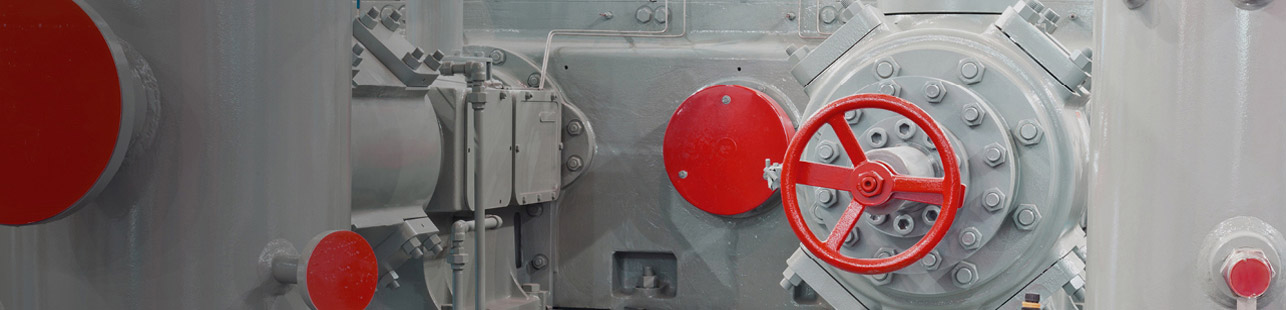

About Komteks:

Komteks is the only manufacturer in Turkey that builds direct coupled cooling systems, radial ventilation cooling systems, 2-way cooling systems and LCD electronic cooling systems, all of which possess ISO 9000, TSE and CE certification.

Meryem Kuran,

Owner,

Komteks Kompresör ve Tekstil Sanayi Tic. Ltd. Sti., Adana, Turkey

(PDF, 272 KB)

Komteks’ service agreement with their customers guarantees service on all supplied compressors for 6,000 hours (250 days), but Komteks was unable to find a compressor oil that could last that long. Customers complained their existing oil foamed and oxidized, turning black due to oil degradation after only 2,000 hours. This region experiences extremely hot and humid weather conditions with temperatures averaging up to 45°C. Komteks needed a compressor oil that would be able to withstand their climate and reduce the need for multiple service visits throughout the length of their service agreement.

Komteks immediately realized significant improvements in customer satisfaction, maintenance demands of their compressors, and the way the oil responded to hot and humid working conditions. “We no longer heard complaints from customers and stopped getting service requests on products we guaranteed would function better and longer than they had been previously. COMPRO XL-S 68 enabled us to keep our promise to our customers.”

Petro-Canada COMPRO XL-S 68 performs to withstand high heat and humidity while remaining effective even at 6,000 hours. COMPRO XL-S 68 had no foaming or discolouration. To date, service calls have been reduced from 42 service calls in one year, at $500 USD per call, to zero calls after making the switch. “Since we made the switch in December 2013, we have been able to fulfill numerous service agreements without a single request for unscheduled maintenance. This has saved our customers, and us, time and money.”

Manny Garcia,

Plant Maintenance Engineer,

Master Molded Products, Elgin, IL, USA

David Moore,

Plant Manager,

Auto Mats and Accessories

Gabriele Fiani,

Technical Manager,

MGF Compressors SRL